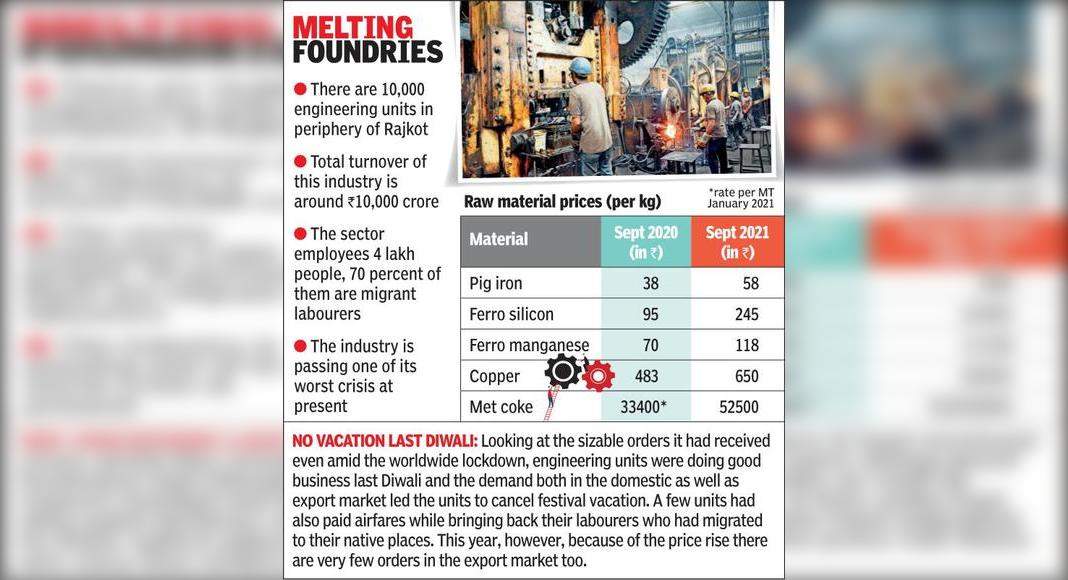

Rajkot: Steam loss over the global coal crisis, the largest industrial cluster of Rajkot, the engineering sector, contemplating a long diwali vacation for the ups and downs of the crisis that began with the increase in raw material prices.

Casting casting and forging units supplies various engineering products to various industries throughout the country, have cut production by 30 percent.

Incidentally, even after the induced pandemic locking carrying the industrial knelt, it rises back and raised ahead when the coal crisis came as another blow to the industry, in particular, the casting of cast iron products which mostly depend on coal.

or electricity for fuel.

Nearly 50 percent of casting in Rajkot still depends on coal.

Foundry makes cast iron products that need a temperature of 1,440 degrees to melt iron ore to make products used in building materials, submersible pumps, auto parts and a number of other machines.

The casting industry itself also uses coal as fuel.

Fuel costs are around 40 percent of the total cost of raw materials.

The Rajkot Engineering meeting was held last week where it was decided to increase prices and limit credit up to 30 days from 45 to 60 days earlier.

After the meeting, the association sent a circular to its members stating: “Increasing costs will not save other castings and industries but surely the industry is in the threshold and will affect production costs.

In particular it will increase unemployment due to industrial closure.” According to sources Industry, raw material prices such as pig iron, coal, silicon, magnesium, graphite, and memos increased by 80 percent since July 2020.

The majority of workers in casting and casting are migrant workers.

Paresh Vasani, President of the Rajkot Engineering Association (REA) said “in casting and forging there is a steep increase in the raw material for forging casting.

Coal prices reach Rs 54.50 per kg from RS 26.

Production costs increase in the way we must suffer even if we will carry out the existing command.

This is a tremendous situation where we make losses with only sustainable production.

“Parth Ganatra, Vice President of the Chamber of Commerce and Industry Rajkot said,” There are many units that provide three holidays in a week and many more units Mulling 20 to 30 days on vacation Diwali.

The increase in coal prices in the last three-four months is mortal punches for the industry and this is a time unit that must be considered to move to solar energy.

“Industrialist Brijesh Dudhagara said,” We do not have orders now because The buyer is unable to pay more.

This is Diwali’s time and we don’t want to damage the festival for our employees.

But if the situation continues, many units will not open after vacation Diwali.

“